China Machining Parts provides 5 axis CNC machining services that achieve an angular tolerance of two-thousandths of a degree (.002°). We specialize in true 5 axis contour machining, manufacturing “almost impossible to make” 5 axis components with ease. It takes more than just excellent machining and programming skills to perform true 5 axis work. Our manufacturing engineers are remarkable machinists and have been with China for 20 - 30+ years. They fix, program, and set up the machines, as well as produce the components themselves, running the job until all the fine-tuning is complete no matter how complex the parts are that an order calls for.

China Machining Parts provides 5 axis CNC machining services that achieve an angular tolerance of two-thousandths of a degree (.002°). We specialize in true 5 axis contour machining, manufacturing “almost impossible to make” 5 axis components with ease. It takes more than just excellent machining and programming skills to perform true 5 axis work. Our manufacturing engineers are remarkable machinists and have been with China for 20 - 30+ years. They fix, program, and set up the machines, as well as produce the components themselves, running the job until all the fine-tuning is complete no matter how complex the parts are that an order calls for.

| |

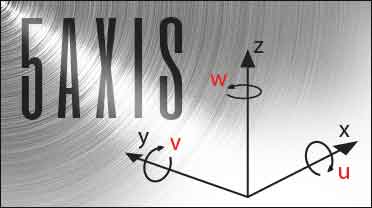

5 axis machining is unique in its ability to effectively process part sizes and shapes with essentially infinite possibilities. Like 3 axis machines, the cutting tool of a 5 axis machining center moves across the X, Y, and Z linear axes, but also rotates on the A and B axes – allowing the cutting tool to approach components from any direction. An experienced machinist can achieve incredibly complicated geometries with high precision when using all 5 axes in conjunction. The skilled and highly experienced CNC machinists and programmers at China Machining Parts are capable of machining complex shapes, undercuts, and complicated angles – all in one setup to boot.

5 axis machining is unique in its ability to effectively process part sizes and shapes with essentially infinite possibilities. Like 3 axis machines, the cutting tool of a 5 axis machining center moves across the X, Y, and Z linear axes, but also rotates on the A and B axes – allowing the cutting tool to approach components from any direction. An experienced machinist can achieve incredibly complicated geometries with high precision when using all 5 axes in conjunction. The skilled and highly experienced CNC machinists and programmers at China Machining Parts are capable of machining complex shapes, undercuts, and complicated angles – all in one setup to boot.

The ability to machine a component to completion in a single setup not only adds to the precision achieved during machining but also reduces tooling costs, overhead costs, and labor time, resulting in the lowest possible cost per part. 5 axis machining centers eliminate several inadequacies of conventional CNC machining techniques, including multiple setups, part transfers, and inspections; part handling, and errors associated with human involvement/interference.

5 axis machining is used across a number of industries to produce precision dependent components with fast manufacturing times and repeatable accuracy, including:

China Machining Parts serves these industries and more, consistently exceeding industry quality standards and the capabilities of normal CNC machine shops. We are happy to take on prototype or production machining work.

Understanding the full capabilities for 5-axis machining is the difference between an ordinary component and an extraordinary one. CNC machinists trained to use CNC machines may not have the knowledge or expertise to get the most from 5-axis technology, but China Machining Parts is different. We have an arsenal of the best 5-axis machinery on the market produced by the best brands, and are always operated by expert machinists who know how to utilize 5-axis technology for your particular components.

China uses the best CNC machines manufactured by AGIE, Hermle, DMG, Okuma, and more. We have consistently delivered remarkable results using our 5-axis machining services for multiple industries all over the China.

While electrical discharge machining is a more popular choice in medical machining, 5 axis milling still plays a key role in certain medical, dental, and ophthalmic applications. If you’re manufacturing medical devices, surgical instrumentation, or other related equipment, China can handle your 5-axis machining demands; delivering the highest precision results. Our engineers are dedicated to achieving the exact specifications you set forth; ensuring the deliverables promised to you are recieved on time and within budget. With decades of experience working with medical product manufacturers, designers, and engineers, you can trust our machine shop to complete the job as expected.

Some of the medical products 4-axis or 5-axis machined by China includes:

In many cases, a 3 axis CNC machine can do the work of a 5 axis CNC machine – not to say with the exact same precision. The main difference is the setup and fixturing time. Setting up a single job on a 3 axis CNC machine can take 5 hours for one piece, including the rotations needed to complete the fabrication. Setup and fixturing of the same job on a 5 axis CNC machine would take less than 2 hours. Cycle time is also significantly decreased by using a 5 axis machine over a 3 axis machine, reducing it by more than 1/3rd.

And, for repeat jobs, once the initial setup has been completed, the next time the job rolls around it is finished much quicker since the specifications are already programmed into the machine. Less time spent setting up and fixturing machines means better turnaround times, and more opportunities to take on other jobs.

We strive to be the premier Machine Shop for the China, producing quality products that won’t fail when put to the test.

Jobs We Have Completed using 5 Axis Machining:

The benefits of 5 axis machining aren’t limited to their precision cutting and curved hole cutting capabilities. The entire production process is improved when 3 axis capabilities upgrade to 5 axis capabilities, opening the door for new possibilities in future jobs.

| |

When searching for 5-axis CNC machining services, look no further than China Machining Parts. Not only do we employ the best machinists to deliver quality with every project, we have industry-leading machinery to ensure you get the most precise finished product possible.

Having seasoned professionals is only half the equation. With today’s technology, only the highest quality 5-axis machines can produce the highest quality products. China Machining Parts boasts an arsenal of the best 5-axis machinery on the market produced by the best brands. AGIECharmilles, Hermle, and DMG MORI 5-axis machines lead the way year after year in precision and innovation.

Don’t leave your project to a machining service with anything less than the best, contact China Machining Parts today to learn more about how our 5-axis machines paired with our expert machinists can make the difference.

China Machining Parts has consistently delivered remarkable results using their 5 axis machining services. If you are seeking impeller or turbine work, you know the complexity of this component’s contours. We seek these challenges, knowing our equipment and 5 axis machine operators have the skills to make impellers with the highest accuracy and precision, no matter the size demands.

China Machining Parts has consistently delivered remarkable results using their 5 axis machining services. If you are seeking impeller or turbine work, you know the complexity of this component’s contours. We seek these challenges, knowing our equipment and 5 axis machine operators have the skills to make impellers with the highest accuracy and precision, no matter the size demands.

China has also created inserts that are used for eye glass molding – not the frame but the actual mold for the prescription glasses. Though this may sound simple, it is anything but. Visualize the complex curvatures of a bi-focal lens. Now make it a progressive bi-focal; add astigmatism and off center axes. Many CNC machine shops are not capable of producing the surface tolerance and integrity achieved with the same precision as China’ 5 axis machinists. This is just one example of how our team's mathematical skills benefit customers.

Another example showcasing our incredible dedication to precision is the production of collimators. Collimators demand ultra-high precision and accuracy to create a high number of holes (depending on its size, a collimator can have 500-1000 holes), each next hole pointing at a different angle than the proceeding hole, with a positional accuracy to be within 5µ to 10µ and an angular accuracy to be within +/- 0.002°. China meets these challenges head on, and successfully achieves the exact specifications these components require—accurately machining each hole so they meet at one focal point.

A third example is the main axial impeller used in the heart pump for VAD—Ventricular Assist Devices. When machining medical devices, precision and accuracy is of the utmost importance - China is dedicated to meeting these requirements, delivering precision machined components safe enough to implant within the human body.

Quote from the heart pump manufacturer/customer:

“Your people have achieved, within 6 months, what others took 2 years to make, and your tolerances were better.”

CNC Swiss-type lathes are the newest pieces of equipment available at China Machining Parts – Swiss machined components are all manufactured with ultra-precise tolerances and parts made to the most exact industry standards. Our Tornos Swiss machining lathes provide a cost-effective way to produce micro-machined parts for industries all over the country. Swiss lathes is essentially a machine that feeds stock through a guide bushing, moving and rotating the part on the X-, Y-, and Z-axes. This large range of movement, much like in 5-axis milling, allows for effectively manufactured parts made to the most precise and accurate measures.

If your company needs Swiss machined parts for a particular application, the professionals at China Machining Parts can help. Contact us today to learn more about our CNC Swiss machining capabilities.

Advanced 5-Axis Technology Used in Micro Milling Services

Advanced 5-Axis Technology Used in Micro Milling ServicesOur 5-axis micro milling centers are one of a kind (specially calibrated for the highest precision results), and setting China apart from the competition. A vital role in our micromachining processes, 5 axis milling enables our CNC machinists to produce complex components with the tightest tolerances and exacting accuracies. With only one tool set-up required per part, human involvement is reduced and components are machined with repeatable accuracy and shortened turnaround times.

Clients throughout the nation come to China Machining Parts with their CNC machining challenges, especially for complex components other Machine Shops were incapable of machining to their exact specifications. Our 5-axis milling advancements combined with skillful EDM micromachining experts provide superior products, while making micro manufacturing more efficient. China delivers perfection from 5-axis milling capabilities, guaranteeing client satisfaction in every product. Trust us with all of your micromachining needs, no matter the complexity.

5 Axis CNC Machining requires 5 axis thinking! Yes, it is quite difficult to comprehend cutting strategies in true 5 axis motion. Fortunately, we have a few techno genii who do exactly that!

If you have a very complex project that needs true 5 Axis CNC Machining, China Machining Parts has your answer. Perhaps we can offer you not only the 5 Axis Machining expertise but also lend you an ear to comprehend the very complex nature of your design requirement.

In order to offer only true high precision work, we limit the size of our 5 Axis work envelope to about 14” cube (355.6mm).

Our 5 Axis Wire EDM Machines offer true 5th axis rotary index wire cuts. We have a specially integrated submersible 5th axis indexer to our super precision Wire EDM machines. Often, people refer to the head tilt option, which is common in most Wire EDMs, as being 5th axis work. Actually, in that context, ours would be considered 6 Axis Wire EDM work.

Examples of the application: A customer requested that multiple holes be cut into a plate, but with each hole drilled at a different angle from the preceding one. This is a common requirement in collimators used in Fiber Optic systems. This type of work is best performed using our 5th Axis Machining System, which allows us to offer substantial cost savings to our customers.

We can offer ½ micron (0.00002") positional and .002° angular accuracies.

| |

China’ advanced 5-axis machining technology offers the best precision and tighter tolerances for people working at a tool & die business. Tool & Die is a billion dollar industry which is primarily made up of small businesses and machine shops throughout the China, and the expert CNC engineers at China Machining Parts are here to help your tool & die business with whatever components you need. Our 5-axis machining services allow for the best CNC parts to be made with the tightest tolerances and highest-quality materials.

5-axis milling creates parts with an angular tolerance of two-thousandths of a degree, meaning our precision capabilities are able to achieve what other precision CNC machinists can’t. We’ve manufactured precision parts for a wide range of industries all over the China, and we can build CNC components for your tool & die company while keeping you within budget.

Some machined components we build for companies like yours include:

Our machinists perform ultra-precision 5 Axis Precision Machine work with 5 Micron Tolerance and .0005° angular accuracies.

An example of our 5 Axis Precision Machine Work: We produced keratomes for Lasik surgery. A Keratome is used to slice a 165 microns (.006496") thick slice off the cornea of the eye. This slice had to be +/- 5 micron accurate! We produced the entire cutting head system using our 5 Axis Ultra Precision Machining Centers and our 5 Axis Wire EDM system.

Problem Parts? Impossible Components? In a Hurry? We are happy to help!

Precision 5-Axis Machining |