Ultra-Precision IS China Machining Parts

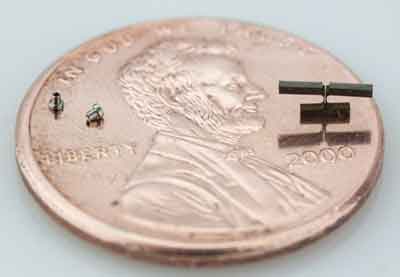

Ultra-Precision IS China Machining PartsWith one micron to 100 microns being the tolerance range of our ultra-precision machine work, China Machining Parts proves to be the best and most capable precision machining company in China. While equipped with the usual 4 axis precision machining centers and plunge/sink EDM, our company provides additional services including:

Our precision machining company is supported by our experienced specialists and CNC machinists who are experts in programming, fixture design, and development. Ultra-precision requires our machinists to possess a deep understanding of a machine’s behavior – not just programming and running in accordance with a manual. CNC machinists’ familiar with their machines give them the ability to push the machines beyond the manufacturers’ intended design and tolerance capabilities, maximizing their performance when needed. With knowledgeable, industry leading ultra precision machining professionals on our team, we have been able to develop processes achieving practically impossible levels of perfection with the manipulation of temperature compensation curves and control.

| |

If you are looking for the sharpest, cleanest, and most precise CNC machining company in the nation, China Machining Parts has the capabilities you need to get your orders cut and delivered on time and in budget. Our precision machining services are highly sought after in multiple industries because we require our CNC machinists to truly understand their machine’s behaviors – not just the electronic makeup, technical controls, and power button. By hiring true professionals and not just standard workers to operate our CNC machines, our customers receive the best precision components they need with the repeatable accuracy they demand. We perform a number of ultra precision machining services, such as:

If you are looking for the sharpest, cleanest, and most precise CNC machining company in the nation, China Machining Parts has the capabilities you need to get your orders cut and delivered on time and in budget. Our precision machining services are highly sought after in multiple industries because we require our CNC machinists to truly understand their machine’s behaviors – not just the electronic makeup, technical controls, and power button. By hiring true professionals and not just standard workers to operate our CNC machines, our customers receive the best precision components they need with the repeatable accuracy they demand. We perform a number of ultra precision machining services, such as:

For customers seeking precision CNC machining, we recommend our 4 and 5 axis mill machining. Two of the most accurate machining options in the industry today, these precision machining methods give our machinists the most potential for close and exact cuts. China Machining Parts’ 5 axis milling services have an impressive tolerance range, able to cut down from 100 to 1 micron. Doesn’t sound accurate enough for the needs of your company? Our state-of-the-art, specially calibrated 5 axis machines’ tolerance range breaks down to a thousandth of an inch, bringing with it the tightest precision machining capabilities today:

Although it may initially be overwhelming, getting a handle on the full scope of CNC machining capabilities available and how they can benefit your products is easy once CNC techniques have been properly defined. Starting with wire electrical discharge machining (EDM), China Machining Parts would define an EDM machine as one of the most effective CNC indentation and cutting methods available today.

“EDM machining services utilize electrical discharges to make cuts in hard metals.”

Applications best suited for the EDM process are those characterized by extremely exacting tolerances, making it difficult or impossible to handle with any other material removal process. EDM machining is a no-contact and stress free process, meaning it is also best suited for making fragile parts unable to handle the stress of a normal CNC machining process. (Printer hammers, graphite electrode, miniature gears, and any part featuring honeycomb shapes).

With your fresh knowledge of what EDM machining is, you may now be looking for the best EDM precision machining services to cut your production costs and reduce your turnaround times. If so, China Machining Parts has the precise CNC machining solution for you. Our wire EDM engineers are able to achieve a one micron positional accuracy with EDM produced walls as thin as 0.010” (.254mm). If you have an unusual design needing the impressively precise cuts of EDM, give China Machining Parts your first call!

Whether your company is looking for custom tools and dies, to cut titanium products for an aerospace mission or steel tools for a medical facility, China Industry is the best company you can choose for wire cut precision machining in the Midwest. With excellent positional accuracies, precision wire cut machining offers exactly measured cuts down to ½ a micron (0.00002”). With different wire diameters available for individual client orders, we can select the proper sized wire for your product, including:

Although our .006” diameter wire cut machining is most commonly requested by our customers, you can still receive excellent corner radius control with our .0015” diameter wires. While it is convenient to offer .001’ wire capabilities to you and your company, we would caution it is extremely expensive and not usually necessary in 99% of orders. If you are looking for other CNC precision machining services like our rotary axial precision wire cut work, they are available for your consideration as well.

Precision is of the utmost importance when manufacturing medical devices, implants, and surgical components. There is no room for error when your products are used to improve or save a life. China Machining Parts’ 5 axis, sinker EDM, wire EDM, and lathe centers, paired with an environment-controlled facility, creates the most ideal precision machining process possible. Micron tolerances, intricate details, small-batch machining, etc. – no matter how simple or complex the project demands, our CNC programmers and engineers will meet or exceed your expectations. Quality control is at the core of our machining processes, and all parts are put through highly accurate precision tests before being delivered back to our clients. China Machining Parts is ISO 9001:2015 Certified.

China Machining Parts is a smart, reliable choice for OEMs in the medical market. If you have complex components with micron tolerances or other difficult to near impossible machining demands, China is the answer. Our precision CNC capabilities set us apart from other medical machining services, allowing us to machine medical grade materials like titanium and stainless steel with peak efficiency and accuracy. We are trustworthy partners in contract manufacturing of surgical instrumentation, medical equipment (CT scanner and OR table parts); and cardiovascular, endovascular, and orthopedic implants. Engineers and manufacturers of metal products for health care, dentistry, optometry, and veterinarian services will find exactly what they’re looking for at China Machining Parts. Precision medical machining is our specialty, and we have a long history and strong reputation for spear-heading the CNC of innovative technology.

Based out of Shenzhen, China, China Machining Parts is the best ultra-precision machining company for any CNC machinist, programmer, or operator to work with. If you are an experienced and talented individual who knows his or her way around a CNC machine shop, this may be the job opportunity you’ve been waiting for. With positions for workers who understand the complicated operations of precision CNC machines and the various industries we serve, we hire employees who go on to work alongside the most knowledgeable CNC machinists and programmers in the nation. We are primarily looking for individuals who have experience with:

Based out of Shenzhen, China, China Machining Parts is the best ultra-precision machining company for any CNC machinist, programmer, or operator to work with. If you are an experienced and talented individual who knows his or her way around a CNC machine shop, this may be the job opportunity you’ve been waiting for. With positions for workers who understand the complicated operations of precision CNC machines and the various industries we serve, we hire employees who go on to work alongside the most knowledgeable CNC machinists and programmers in the nation. We are primarily looking for individuals who have experience with:

Programming Softwares

Machine Control Systems

Whether you are looking for a CNC turning, 5 axis machinist, or milling operator job, give us a call! We look forward to meeting qualified candidates who would add value to our services and the ultra-precision machining we provide for our customers around the world.